CSP process is the latest and strongest masterpiece on behalf of LED,

indicating that the future CSP lamp belt will be the mainstream of the market,

but also will enter thousands of households.

So CSP process lamp belt in the end in what aspects can the market shine?

CSP LED light beads Using advanced gold-free flip chip packaging technology

At present, it has CSP roll-to-roll flexible light strip automation process technology

of companies are few and far between And Coolight is on the list of successes

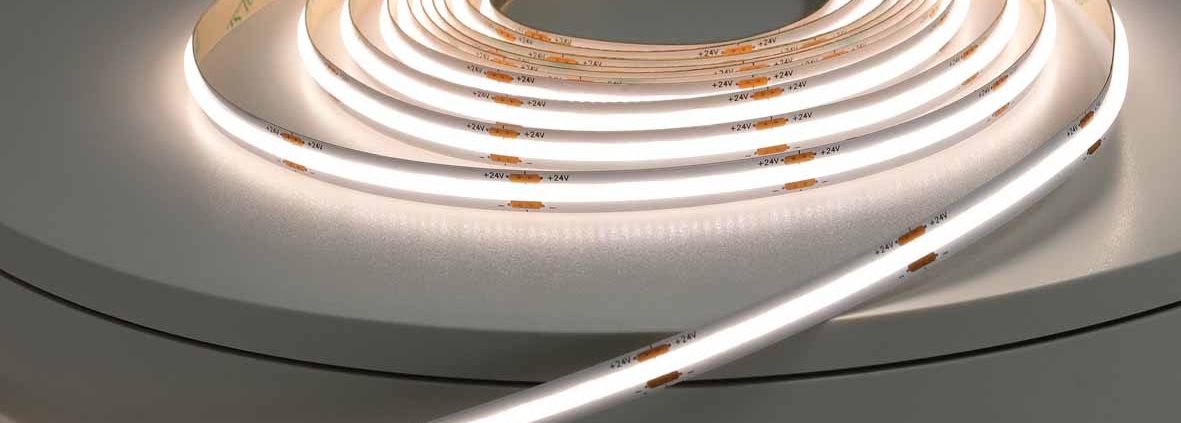

The arrangement density of light beads is clearly visible Uniform light without spot

Roll-to-roll extra long board The whole meter does not need welding better reliability

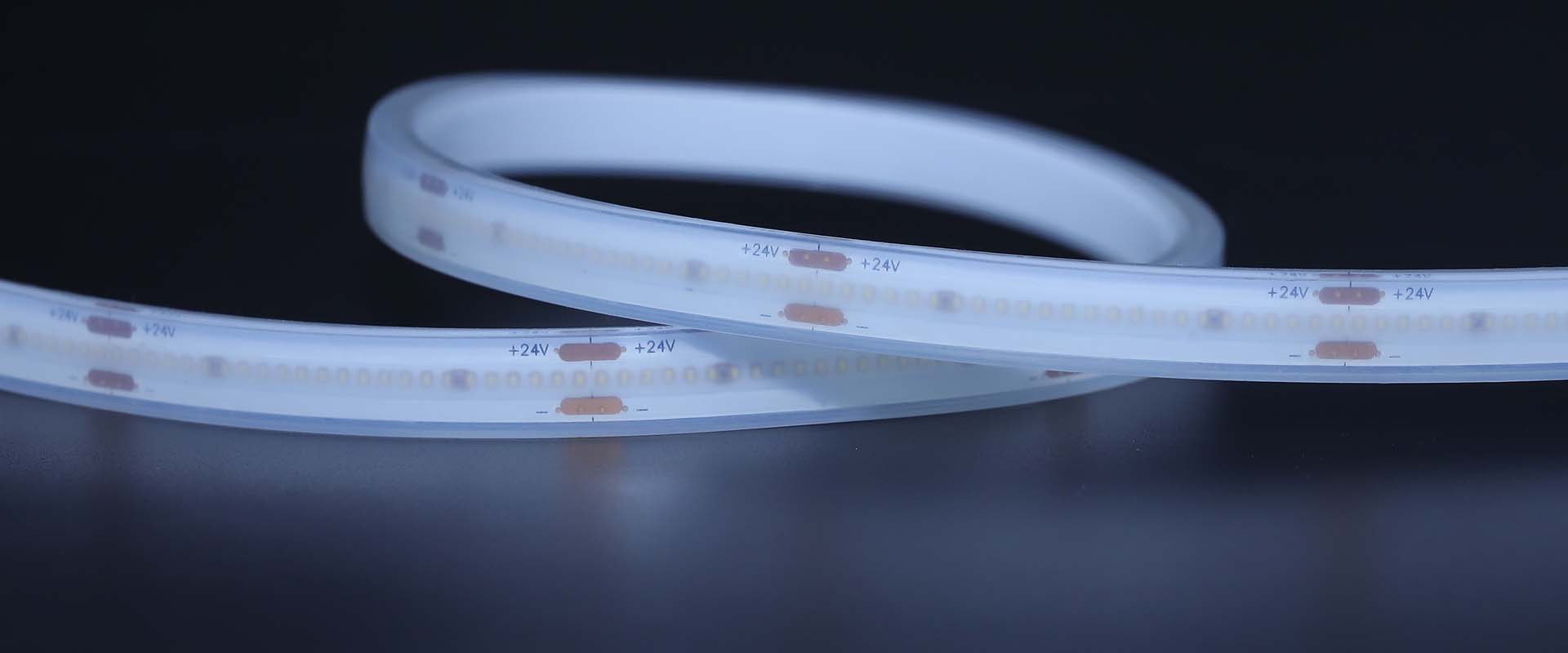

Extrusion process, colloidal transparent, smooth surface SDCM≤3

Compared with the traditional COB light strip with glue-dropping process It has better luminous consistency

CSP light strips are relatively softer Bending angle is smaller This is also not achieved by many light strip products

on the market today.Of course, compared to COB’s soft light and regular SMD’s grainy light

CSP obviously has better light transmittance and higher light efficiency The energy release is more powerful!

Think about the future room without big crystal lamps,Instead, it is a hidden CSP light strip,Make our room “bigger”, more beautiful and clean.

100m long without welding Every 50MM can be cut No fear of space length restrictions